Is that really concrete?

Concrete in most cases will not conjure thoughts of beautiful and aesthetically appealing environments, still we use concrete almost without exception in all buildings we construct.

Concrete has been around for centuries, the Romans widely used concrete to build some of their most impressive constructions (the Pantheon in Rome was built in about 120AD and is still the largest unreinforced concrete dome in the world). Around the Mediterranean, aqueducts, drainage systems and amphitheatres built using concrete 2000 years ago can still be found. It wasn't until the 1990s however that concrete was discovered (by accident) to produce the highly durable and attractive surfaces we know today as polished concrete.

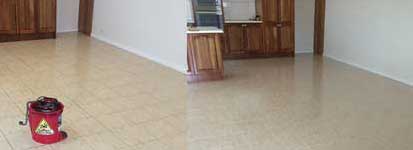

Long relegated to life as a sub-floor, interior concrete slabs have been hidden under flooring materials such as carpet, hardwood, vinyl or ceramic tile. But why waste resources and money to add another layer of flooring when you can simply leave the concrete exposed?

When considering the life-span of an overlayment, the process represents expensive installation, ongoing maintenance and eventual replacement costs, however in all circumstances the underlying structural concrete remains. Polishing concrete eliminates the need for overlayments by converting the actual existing concrete into an economical, durable and low maintenance finished surface with spectacular visual appeal.

Want a floor that looks amazing, is easy to clean and durable?

To schedule your appointment or to obtain a free estimate, call 1300 771 201 today or use our online enquiry form

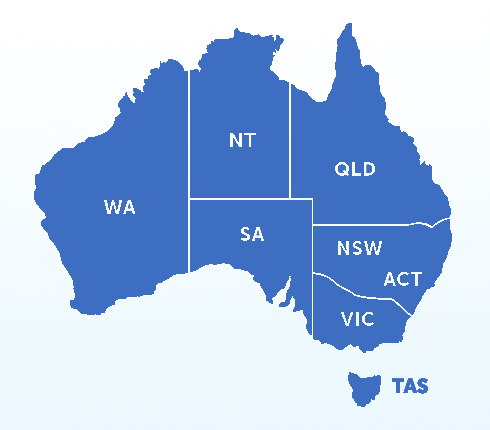

We cover all Hobart suburbs, all Kingborough area and all surrounding suburbs to Kingston Beach

Availability for emergency

Availability for emergency

-->

-->